For operators seeking reliable, high-performance tarping systems, O’Brian Tarping Systems delivers with two proven solutions: the Diablo Hoist Tarping System and Magnum-XD: Extreme Duty Tarping System. These systems have long been trusted for their durability, efficiency, and exceptional coverage across a range of container sizes.

The Diablo features the lowest profile arms in the industry, specifically designed to prevent arm damage during container loading and unloading from the truck. This design ensures that the arms remain intact even in the toughest conditions, reducing maintenance costs and downtime. Meanwhile, the Magnum is built for the most demanding jobs, making it the Extreme Duty solution for those requiring extra strength and endurance.

Patented Technology for Superior Coverage

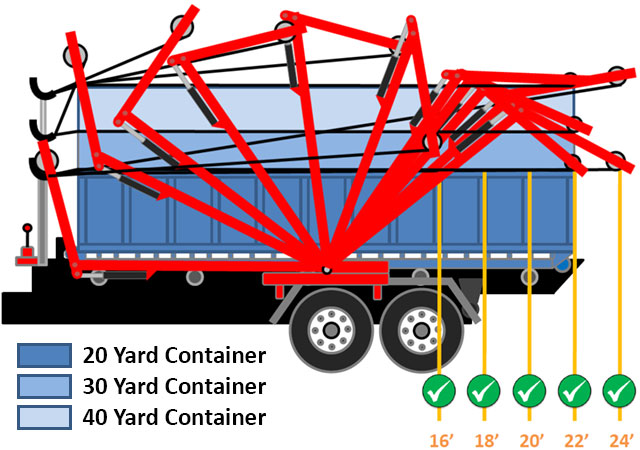

A standout feature of O’Brian’s tarping systems is their patented Pivoting Upper Arms, which provide superior coverage compared to competitors. These arms adjust to accommodate a wide range of container sizes, from 10-40 cubic yards for the Diablo and up to 50 cubic yards for the Magnum. Whether you’re working with containers between 16 and 22 feet (up to 24 feet for the Magnum), O’Brian systems deliver comprehensive coverage, ensuring that the entire top of the container is securely protected with no gaps.

Competitor systems that use “Sliding Pivot Points with Fixed Arms” or “Telescoping Upper Arms” often leave the tarp hanging off the back of shorter containers, which can lead to unsafe conditions and tarp damage. O’Brian’s pivoting elbow upper arms allow the tarp roller to extend fully to the rear of the container, offering better protection, extending tarp life, and preventing debris from blowing out.

Ease of Use and Operator Safety

Both the Diablo and Magnum tarping systems are designed with operator safety and ease of use in mind. The tarps are simple to deploy and retract using controls mounted next to the cab. This design keeps the operator safely away from moving parts, reducing the risk of injury while maintaining efficient operation.

Maximized Durability and Long-Term Value

By positioning the tarp roller at the rear of the container, O’Brian tarping systems minimize wear and tear on both the tarp and the arms, increasing the lifespan of the entire system. This also helps avoid costly repairs and replacements. When compared to competitor systems, which often struggle with shorter containers and leave the tarp vulnerable, O’Brian’s patented design ensures reliable coverage and durability for the long haul.

Systems with Sliding Pivot Points and Fixed Arms or Telescoping Upper Arms create issues like hanging tarps on shorter containers, leading to increased wear. In addition, some competitor systems place the control mechanisms too close to the arms, posing potential safety hazards such as head injuries during operation.

The O’Brian Advantage: Proven Tarping Systems

When you choose O’Brian Tarping Systems, you’re investing in field-tested, high-performance solutions that deliver better coverage, longer equipment life, and enhanced operator safety. Whether you need the low-profile design of the Diablo or the extreme durability of the Magnum, O’Brian’s systems ensure that your load is secure, your equipment stays protected, and your operation runs smoothly.

Ready to Maximize Your Tarping System?

If you’re looking for a tarping solution that stands up to daily use, improves safety, and delivers unmatched coverage, it’s time to choose O’Brian Tarping Systems. Contact us today to learn more about the Diablo and Magnum systems and how they can revolutionize your operations. Don’t wait—upgrade your tarping system and start experiencing the O’Brian advantage.